ما هي واجهة ؟ نوع واجهة

2022-09-05.

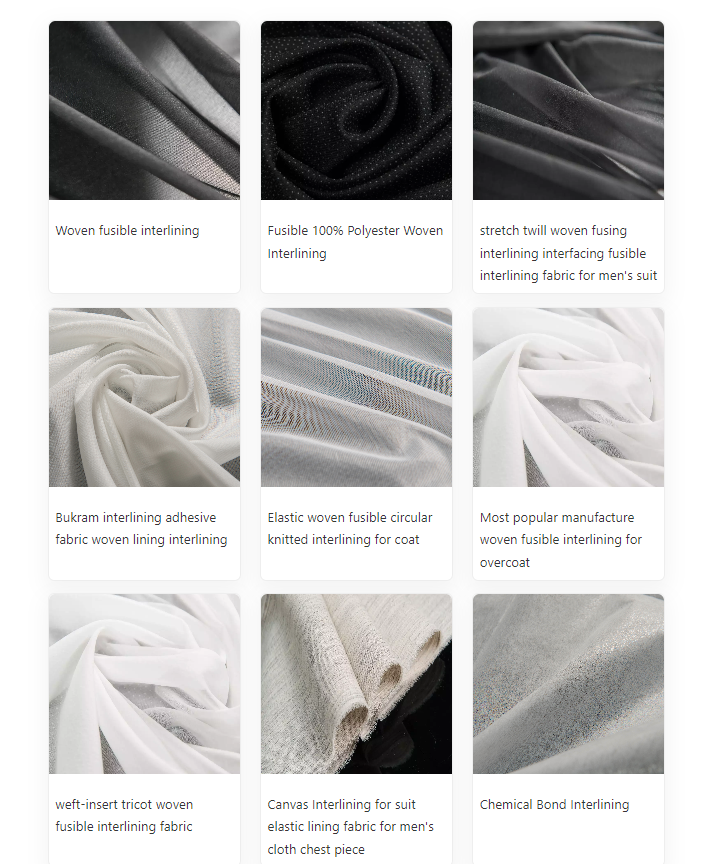

Definition Of Interfacing

Interfacing is a woven fabric, knitted fabric and non-woven fabric as the base fabric, using (or not using) thermoplastic polymer compounds, through special machinery for special finishing process, used for the inner layer of the garment to play the role of reinforcement, bracing, etc., and the fabric bonded (or non-bonded) special garment accessories.

Types Of Interfacing

The major categories are non-woven and woven, and garment interfacing is generally divided into non woven and woven.

1. Non woven, as the name implies, is a cloth formed without being woven.

Process principle: the viscose used for chemical fiber is treated with high temperature and pressure to form a base cloth. Then a layer of hot melt adhesive is applied on the surface of the base cloth through the coating machine, and then the non woven interfacing used by us is formed through drying.

Usage: put the adhesive side of the interfacing on the fabric, and then heat it with a bonding machine or iron to melt the adhesive on the interfacing, so as to achieve the effect of bonding on the fabric.

Features: cheap, soft, but not washable.

2. There is spinning. The commonly used equipment is a key bar loom and a water jet loom. Polyester is woven into a base cloth. It is characterized by strong tensile force and good elasticity.

As for the adhesive of lining cloth, powder spreading adhesive was usually used in the market in the past. Its characteristics are large amount of adhesive and simple production process. The disadvantage is that it is easy to produce glue penetration due to large amount of adhesive. Now it has been eliminated.

At present, the most advanced is the two-point process without foundation make-up paste, which is characterized by easy control of the amount of glue, strong adhesion, water washing resistance and other special treatments. It is now used by most manufacturers.

Classification by use

1. Shirt adhesive lining: it is required to be washable, with small shrinkage, stiff and elastic. The base fabric is woven fabric and PE or pet glue is used.

2. Coat adhesive lining: it is required to be resistant to dry cleaning and washing, soft and elastic. The base fabric can be woven fabric, knitted fabric, non-woven fabric, PA, pet or PVC glue.

3. Leather adhesive lining: low pressing temperature, soft feel and poor washability are required. Woven fabric and heavy textile fabric are used for the base cloth, and EVA or PA glue is used.

4. Shoes and hats and decorative adhesive lining: low pressing temperature, low price and poor washing resistance are required. The base cloth is made of non-woven fabric, woven fabric or foam plastic, and EVA, PE or PVC glue can be used.